Sewage tank protection: prevention is far better than cureIssuing time:2025-02-18 15:09 In 2021, news about a sewage tank leak in Florida, USA, drew widespread attention. The tank stored approximately 480 million gallons of wastewater containing nitrogen, phosphorus, ammonia, and trace amounts of radium and uranium. The leak led to the emergency evacuation of over 300 households. More critically, the sewage tank was located near a waterway flowing into Tampa Bay. To date, millions of gallons of wastewater have been discharged into Tampa Bay, causing massive deaths of algae and fish in the nearby waters and posing significant harm to the surrounding environment. A $15.4 million wastewater discharge plan has now been initiated. Although sewage tank protection projects may seem distant from our daily lives, they are closely related to our living conditions and the environment. A single project can impact thousands of households and the environment we depend on for survival. The importance of sewage tank protection is evident, and selecting the right protective materials has become key to ensuring project quality! Through years of scientific research and practical application, polyurea materials have proven effective in preventing damage and erosion caused by various substances such as bacteria, acids, alkalis, and salts. They also effectively avoid environmental pollution issues caused by liquid leaks. Traditional thinking cannot meet new requirements

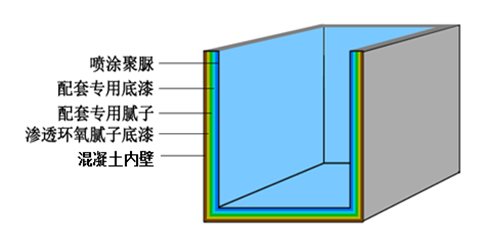

Advantages of Polyurea Materials in Sewage Tank Corrosion Protection Compared to traditional anti-corrosion materials, polyurea materials offer several key advantages in sewage tank applications:

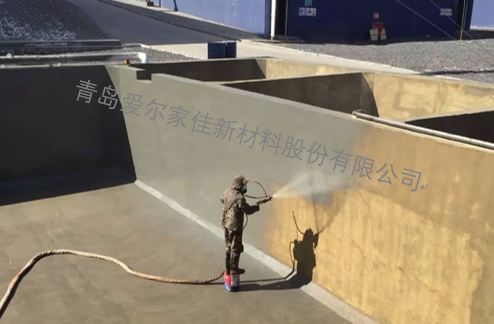

Sewage tank protection: prevention is far better than cure The most critical challenges in sewage tank protection projects are durability and diversity, and the overarching principle is that prevention is far superior to remediation. Sewage treatment plants handle massive daily wastewater volumes, and even a single day of shutdown for maintenance can strain the system's capacity. Additionally, different application scenarios—such as municipal sewage tanks, petrochemical plants, thermal power plants, nuclear power plants, and waste-to-energy plants—involve varying liquid compositions in their sewage tanks. Therefore, when addressing sewage tank corrosion protection, it is essential to select specialized polyurea products that offer long-term protection tailored to the unique characteristics and environmental conditions of each project. With over a decade of expertise in polyurea anti-corrosion solutions, Air++ has accumulated extensive experience in product formulation, selection, and construction. We provide customized polyurea services for various projects, conducting detailed and professional analysis of specific working conditions to effectively solve your protection challenges. Our technology and products have been widely applied in numerous projects, including the Yantai Wanhua sewage tank, Sinochem Environment's Shenyang Renewable Resources Industrial Park project, the high- and low-concentration biochemical wastewater treatment tanks at Sinopec's Zhongke Refining and Chemical facility, and the sewage tanks at Rizhao Steel Company, earning high praise from our clients. Environmental protection is no small matter, and prevention is always better than cure. Air++ is here to walk this path with you! |