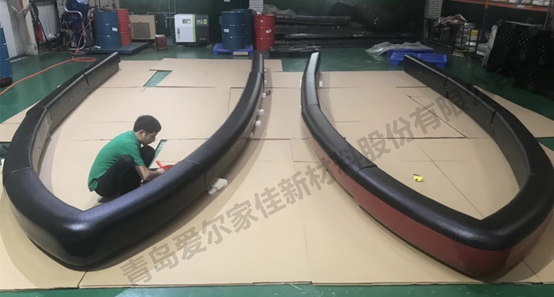

Polyurea: Taking Action in Disaster Resistance and ReliefIssuing time:2025-02-18 15:13   Fiberglass speedboats and rescue boats possess strength comparable to steel, excellent stability, and are suitable for use in high winds, rough waves, and strong currents. They offer high safety and are most commonly used in harsh disaster rescue conditions. Aluminum alloy speedboats and rescue boats, on the other hand, are characterized by their low density, lightweight, portability, durability, and ease of launching. They are more frequently used after floodwaters have stabilized. However, whether made of fiberglass or aluminum alloy, if no protective measures are applied, the hulls can suffer damage and thinning due to frequent friction and environmental erosion. Damage caused by sharp or hard objects during rescue operations can significantly shorten the lifespan of these lifeboats and rescue vessels. How can this problem be solved? Polyurea high-performance safety coatings are the best choice! They exhibit excellent adhesion to both fiberglass and metal substrates and are lightweight, adding no extra weight to the hull. By forming a dense protective layer on the hull's surface, polyurea coatings provide effective protection with their superior physical properties. They are not only waterproof and corrosion-resistant but, most importantly, wear-resistant and impact-resistant, preventing damage caused by complex environments during rescue operations. Even during non-rescue periods, this "protective layer" eliminates the need for additional anti-corrosion measures and significantly enhances the hull's aging resistance, reducing the maintenance costs of rescue vessels.  In addition to the two types of hulls mentioned above, rubber inflatable motorboats are more practical during search and rescue operations, especially when rescuing a small number of people in villages or remote areas. These boats are highly flexible, easy to transport, and can be inflated and used on demand. They also provide excellent impact resistance and cushioning. However, their biggest drawback is their fragility—they are prone to wear, scratches, damage, punctures, UV degradation, and chemical corrosion. Once the hull is cracked, the boat cannot be used until repaired, and metal parts require additional anti-corrosion treatments.   |